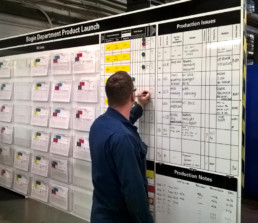

6S boards

Any business that cares about successful production as well as employee safety can benefit from practicing S6 programs. While 5S principles are great for the production aspect of a business, 6S joins all processes with safety. The use of a 6S board provides your workplace with an invaluable visual tool to help everyone in the workplace operate consistently and mindfully.

Safe and Streamlined Success

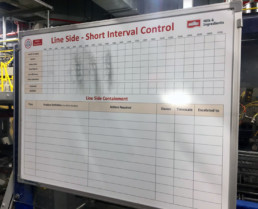

With a 6S board, safety truly is the priority when it comes to smooth productivity. Using the 6S board and running 6S lean programs can help any business to achieve better productivity and a team mentality when it comes to processes in a workplace.

The right 6S board can help to reduce waste management, bring down production costs, prevent machines from needing frequent repairs, and more. A business can also start producing more high-quality products and increase employee engagement when using the 6S as a tool for safer productivity.

A Simple Upgrade

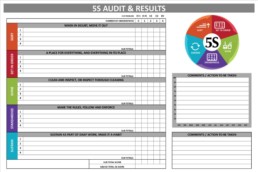

If a business already adheres to 5S principles, adding 6S lean introduces safety to an already highly productive work environment. Any management that values safety just as much as high-quality productivity knows that visual reminders can benefit every person in a work area. This is where a 6S board can be useful.

Using a 6S board to organize principles and progress in a workplace can unite an entire department or team for smoother operations. A well-placed board gives an easy-to-follow and understandable tool to prevent confusion while prioritizing communication.

Once you know the steps you want to follow using 6S, you’ll be ready to use your 6S board. With your board, you and your team can focus on reducing clutter, improving efficiency, and more.

Many businesses use “red tags” to indicate items that are not necessary and can be disposed of immediately. A “yellow tag” refers to items that are still necessary, but may not be needed until sometime soon. Most businesses will move their yellow-tagged items off-site to minimize clutter. This is just one easy way a 6S board can be useful for a business.

Organize a Thriving Business

When you are ready to move forward, a 6S board can be a great way to organize all aspects of a first step toward improved production and safety. If the workplace finds that they need to adjust throughout their steps, a 6S board makes any change fast and easy.

The safety step of 6S lean is arguably the most important one of all. Using a visual aid to follow and adjust can help a workplace to be able to see potential hazards and adapt as needed.

The benefits of including safety and using a 6S board for identifying problems and tracking changes often leads to better production and improved employee safety. Using a 6S board has been reported to have a positive effect on production speed and quality. Employees also feel less stress and are safe while working.

Benefits Beyond Measure

Possibly the most beneficial impact of using a 6S board is that the entire work environment stays and remains safe. Any employer and their employees stand to benefit from the aid of a 6S board. Our boards do an excellent job of communicating and keeping everyone safe in a work environment.

Müller Milk UK

Our understanding of the manufacturing processes and the requirements within this particular industry has been key to developing a relationship with Müller. We regularly design and manufacture a wide range of KPI boards, vinyl graphics, wall graphics, lean manufacturing solutions and illuminated signage to name a few. Our multi-award winning workshop team manufactures and installs signage projects across multiple sites – utilising the vast experience of working in the food and beverage sector.